Don't Stop (Looking Good)

Looking for a nice the finishing touch to your custom build? Just can't get enough oil slick? You're in the right place.

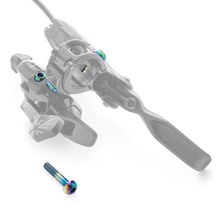

Our custom Matchmaker brake and shift lever hardware kits are precision machined from strong, corrosion-resistant 6/4 titanium and, well, look awesome.

And because some folks have strong feelings about Torx hardware, all four pieces use a 4mm hex instead.

Will they save weight? Maybe! But that's not really the point, is it?

Compatibility:

SRAM and Avid Matchmaker-compatible brake levers with shift levers mounted to the brake clamp.

Important!

These bolts hold your brake levers on. At the same time, you want your shift and brake levers to rotate instead of break in the event of a crash. We recommend the following torques:

- Lever clamp: 4-5Nm

- Shifter to shifter mount: 5-6Nm

- Shifter mount to brake clamp: 4-5Nm

Oil slick rainbow anodizing is an electrochemical process and no two parts will look the same. We attach the electrodes required for finishing in inconspicuous spots, which means that you could see some unusual patterns in parts of your bolts that shouldn't be visible after installation.

Installation:

Click here for detailed installation instructions

Required tools & supplies:

- Bicycle workstand

- Mild cleaner

- Clean rag

- T25 Torx wrench

- 4mm hex wrench

- Torque wrench with

- 4mm hex bit

- Nickel anti-seize compound (preferred), copper anti-seize, or dielectric grease

- Optional:

- Digital level or level app

Repeat the following for each lever:

- With the bike on the ground, use a level (or smartphone level app) to note the angle of your brake levers relative to the grips.

- Mount your bike in the workstand.

- Remove the Torx bolt holding the shift lever to the right shifter mount

- Remove the flat head Torx bolt holding the right shifter mount to the brake clamp

- Note how aluminum t-nut with curved flange sits inside lever clamp

- Remove the Torx bolt holding the right and left lever clamps to each lever body

- Clean your brake levers and clamps with a mild solvent and soft cloth, paying special attention to the clamping surfaces. You don't want dirt, grime, or anything else on your brakes' clamping surfaces.

- Add anti-seize compound to threads of all new bolts.

- Reinstall aluminum T-nut with curved flange in brake lever clamp and install fine titanium flat head bolt through shifter mount into T-nut barrel.

- T-nut threads are very fine and subject to cross-threading: if you feel resistance stop, realign parts, and try again.

- Use 4mm hex key tighten flat head screw to finger-tight but do not torque at this point.

- Make sure that T-nut flange sits in broad brake clamp channel. If it's sitting proud of the bar clamp surface you could scratch or damage your handlebar.

- Reinstall shift lever on shift lever mount using short titanium screw and 4mm hex key.

- Reinstall brake levers on bar using long titanium brake lever clamp bolts.

- Check your (bolt) head: if heads do not sit flat on the Matchmaker clamp remove the bolts and add the provided washer under the head before reinstalling.

- If you have an early kit that does not include washers and you need them, please contact us with your address and we'll get some out right away.

- Remove the bike from the stand and holt or lean upright.

- Loosen the clamp bolt and rotate the levers to the angle noted earlier.

- Using torque wrench and 4mm hex bit torque brake lever clamp bolts to 4-5Nm

- Brake levers should not rotate in normal use.

- Loosen flat head screw holding shift lever mount to brake lever clamp rotate around the bar to a comfortable position.

- Using torque wrench and 4mm hex bit torque flat head titanium screw holding shift lever mount to brake clamp to 4-5Nm

- Using torque wrench and 4mm hex bit torque titanium bolt holding shift lever to shift lever mount to 5-6Nm

- Go for a ride.

As always,

Trademarks are property of their respective owners. Compatibility statements from Terske are not endorsements by trademark holders.